While traditional signal-level hardware-in-the-loop (HIL) tests effectively verify battery management system (BMS) functional strategies, they fail to validate battery pack performance effectively. Real-vehicle road and field tests provide realistic insights, but their limitations in test condition coverage and stringent requirements pose challenges. This case study explains how the China Automotive Technology and Research Center (CATARC) is pioneering advancements in battery testing by implementing a battery-in-the-loop (BIL) simulation system.

Evolving Chinese automotive market

The development of the automobile industry in China is at a pivotal stage, presenting opportunities, risks and challenges. Electric vehicles hold substantial potential to enhance economic and industrial competitiveness, attracting investments in major markets. To address functional safety concerns in automotive software, the industry has established ISO 26262, a critical international standard improving the safety of electrical and electronic systems.

Growing complexity of battery design

Across various countries, research on EVs consistently identifies the battery as the most problematic component. Ensuring battery system safety involves considerations of battery-cell characteristics, module design, pack structure, exhaust design and the dominant role of the BMS. This system is increasingly regarded as the core technology for EV makers, as evidenced by the surge in core intellectual-property rights related to batteries.

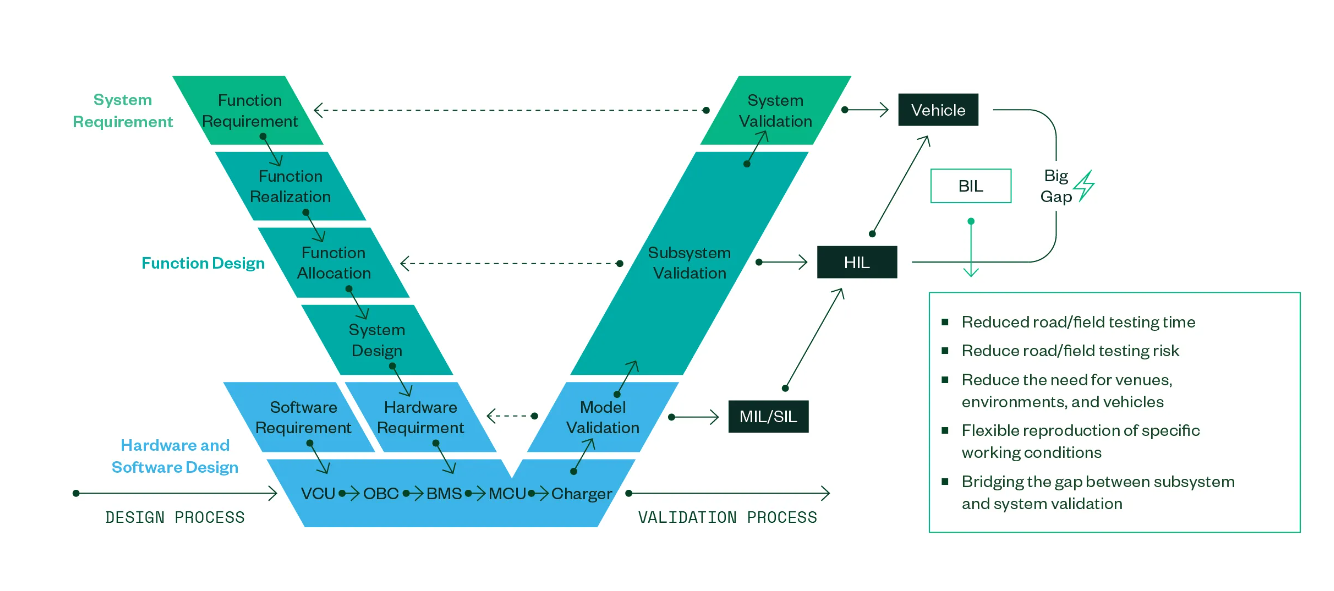

The typical approach in developing and testing EV controllers involves adopting the V-cycle development process, as shown in Figure 1. This process enhances development efficiency, mitigates risks and reduces the overall workload. It efficiently progresses through system requirements, functional requirements, software and hardware design, model- and software-in-the-loop verification, HIL testing and real-vehicle testing. Notably, HIL testing of the controller plays a key role in this process. The HIL test platform establishes a virtual operating environment for the controller, verifying its functions by providing specific input signals and monitoring corresponding output signals.

Figure 1: V-cycle development flow

While the traditional signal-level HIL test is effective for verifying BMS functional strategies, it falls short of verifying battery pack performance. Real-EV road and field tests offer the most realistic assessment of battery pack performance; however, they are limited by narrow test condition coverage and stringent ISO 26262 functional safety requirements. In addition, conducting real-EV tests in specific environments, such as extremely high or low temperatures, demands higher environmental requirements.

BIL real-time simulation platform

In response to these challenges, CATARC employs simulation and testing to introduce a comprehensive set of BIL test solutions. This platform effectively narrows the gap between HIL tests and real-vehicle road and field tests, minimizing the demands for field, environment and vehicle requirements. A comparison of the different test methods is shown in Table 1.

Table 1: Comparison of the road and BIL test methods

The BIL system framework encompasses load simulation, environmental simulation, device under test and vehicle simulation, as shown in Figure 2. It controls the real charging and discharging systems under virtual working conditions, roads and energy requirements.

Figure 2: BIL test system framework

BIL test bridges the gap

CATARC’s BIL test solution emerges as a vital bridge, filling the gap between HIL tests and real-vehicle road tests. It is equipped with essential components, including an environmental chamber, water cooler, virtual load and other equipment to replicate the real working conditions of the battery under numerous scenarios (see Figure 3). Collaborating with a leading carmaker, CATARC has provided BIL testing services, offering a rich library of test cases and driving scenarios.

Figure 3: CATARC’s BIL test scheme

The virtual load emulates both a charging pile and a load to charge and discharge the battery pack. The primary control system communicates seamlessly with the battery virtual load, battery pack environment simulation system and the BMS using the CAN protocol. The BMS in turn employs the CAN protocol to enable the fast-charging functionality. The battery pack’s cooling and heating system handles thermal management and is intricately linked to the main control system through Ethernet, primarily controlled through LabVIEW. Additionally, the vehicle dynamics and road models are built using CarMaker, while other strategy algorithm models are developed with MathWorks MATLAB software and Simulink software.

The system has three specific advantages:

● It simulates various real road and extreme working conditions, which reduces the demand and time of real-vehicle testing.

● It accurately plays back real-vehicle data, finding target performance improvements.

● The interface is open and flexible, enabling it to adapt to the needs of various models.

Through the BIL test system, CATARC realizes a range of test items, including state of X (state of charge, state of energy and state of health), cycle life, capacity calibration, discharge-capacity retention, pulse charge and discharge characteristics, overcharge/overdischarge rate and thermal management. The system facilitates the customization of test scenes, enabling the reproduction of real-vehicle states and environments, simulations of winter/summer standard working conditions and fulfilling the functional safety requirements and testing methods for the BMS according to the GB/T 39086-2020 standard.

About US

Heisener Electronic is a famous international One Stop Purchasing Service Provider of Electronic Components. Based on the concept of Customer-orientation and Innovation, a good process control system, professional management team, advanced inventory management technology, we can provide one-stop electronic component supporting services that Heisener is the preferred partner for all the enterprises and research institutions.