Vehicle electrification is a sector that still has many technical challenges that automakers are focusing on. Electronic designers and engineers of powertrain systems and high-voltage technology systems for a sustainable future are interested in achieving greater range for EVs, reducing design complexity and costs of external components. Maximizing the autonomy of EVs by reducing complexity and design costs is the main objective of the modern automotive vision. The EV ecosystem is strongly influenced by the presence of silicon carbide (SiC) power electronic devices, which allow the system to obtain multiple performance advantages.

The automotive industry is going through a phase of technological transformation. Indeed, the evolution from internal-combustion–engine (ICE) vehicles to electrically powered vehicles is spreading rapidly. In parallel, innovations in the semiconductor market for traction inverter systems and power conversion help overcome critical barriers to ever more widespread use. Driven by regulations around the world to reduce CO2 emissions, electric vehicles will achieve widespread adoption by 2030. As such, designers of high-voltage applications, such as traction inverters, are faced today with addressing a variety of challenges to optimize system efficiency and reliability in a small space. Automotive research further reduces components and speeds prototyping of an efficient system using the SiC EV traction inverter reference design.

Today, automakers can build reliable SiC-based traction inverters and insulated-gate bipolar transistors (IGBTs) with advanced SiC monitoring and protection and diagnostics for functional safety. The latest-generation and highly integrated SiC gate drivers make it possible to maximize the autonomy of EVs. To achieve the goal of increasing the autonomy of EVs, it is also necessary to design more efficient traction inverters. Automotive engineers must design safer and more efficient traction inverters that can increase the range of EVs by up to a few thousand kilometers per year. SiC gate drivers, thanks to their features, allow designers to improve power density, reduce system design complexity and the number of external components, lower costs, achieve strategic objectives in terms of functional safety and overall performance, maximize autonomy and design increasingly efficient traction inverters.

Technical specifications and reference markets of power devices

With SiC gate drivers, you can do much more while consuming less power. This has made them ideal devices suitable for multiple markets, especially in what the automotive market requires today, with advantages in various applications. The new SiC gate drivers offer outstanding characteristics in terms of increased power density, performance and safety.

Efficient power conversion depends on the power semiconductor devices used in the system. High-power applications are becoming more efficient and smaller in size due to improvements in power device technology. These devices include IGBTs and SiC MOSFETs, which are well-suited to high-power applications due to their high voltage ratings, high current ratings and low conduction and switching losses. Applications with voltages greater than 400 V require device voltage ratings greater than 650 V to allow sufficient headroom for safe operation. Applications like industrial motor drives, EVs and hybrid vehicles, traction inverters and solar inverters for renewable energy have a power level from a few kilowatts to a megawatt and beyond.

The applications for SiC MOSFETs and IGBTs have very similar power levels; however, they vary as the frequency increases. SiC MOSFETs are becoming increasingly common in power-factor–correction power supplies, solar inverters, EVs and hybrid vehicles, traction inverters for EVs, motor drives and railways. On the other hand, IGBTs are more common in motor drives, uninterruptible power supplies, string and central solar power inverters below 3 kW and EV/hybrid-vehicle traction inverters.

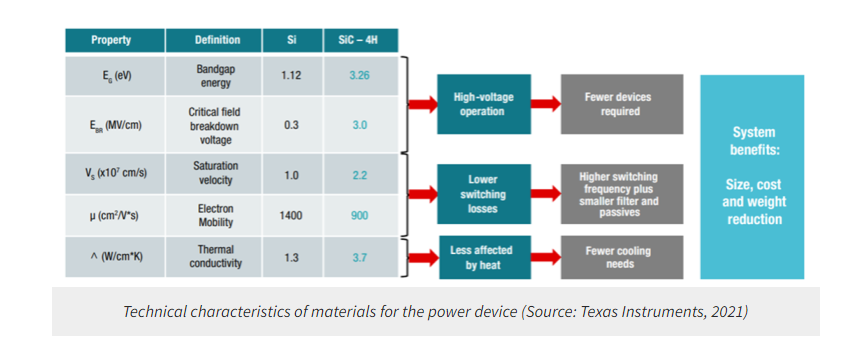

There are also several system advantages of SiC MOSFETs over silicon MOSFETs and IGBTs. First, silicon MOSFETs and IGBTs have been used in power converters for a long time. However, SiC MOSFETs have emerged as a new technology, displaying important advantages that surpass those of other devices due to their inherent material properties. In fact, a wide-bandgap (WBG) material has extremely interesting characteristics. The material properties of SiC translate directly into system-level advantages over systems using Si devices. Key benefits include reduced size, cost and weight. As a result, SiC MOSFETs are increasingly replacing silicon power devices.

Si MOSFETs, Si IGBTs and SiC MOSFETs are used in power applications but differ in power levels, drive methods and operating modes. Power IGBTs and MOSFETs are voltage-driven at the gate, as the IGBT is internally a MOSFET driving a bipolar junction transistor. As a result of the bipolar nature of IGBTs, they carry a large amount of current with a low saturation voltage, resulting in low conduction losses.

MOSFETs also have low conduction losses but depend on the device’s drain-source on-resistance (RDS(on)). Silicon MOSFETs carry less current than IGBTs, so IGBTs are used in high-power applications. MOSFETs are used in high-frequency applications in which high efficiency is paramount.

As for SiC MOSFETs, we can say that they are similar to Si MOSFETs in device type. However, SiC is a WBG material with properties that allow these devices to operate at the same high-power levels as IGBTs while still being able to switch at high frequencies. These properties translate into important benefits, including higher power density, higher efficiency and lower heat dissipation. As power levels increase—for example, in traction inverters that drive EV motors—thermal management of silicon power devices like IGBTs becomes more complicated due to high-limit operating temperatures and allowable junction temperatures. This involves incorporating cooling components into drive systems, especially in a traction inverter, where power levels can exceed 100 kW. However, these cooling components increase the size, weight and cost of the vehicle. In contrast, SiC has a much higher allowable junction temperature. Additionally, for a given battery capacity, SiC circuit breakers offer a 10% efficiency improvement over IGBTs in the traction inverter system.

The importance of SiC in automotive power electronic systems

SiC, a third-generation broadband semiconductor, has established itself in recent years as a successful technology that has the potential for a global impact on the sustainable transport ecosystem. The use of SiC for power switches enables higher power densities and switching efficiencies in EV powertrains. There are several advantages to derive from the adoption of SiC, which can be obtained by exploiting the highly differentiated set of SiC material properties to design more efficient, robust and compact propulsion systems.

We can thus summarize the main advantages of power electronics based on SiC as follows:

● Increased power density for improved performance of EV powertrains

● Ability to operate at higher temperatures than traditional silicon-based devices

● Increased current-carrying capacity

● Higher switching frequencies

● High withstand voltage

● A 2× to 3× higher thermal conductivity than that of silicon

● Increased driving range

● Faster charging

● Cost reduction

SiC power devices can carry current densities up to 5× higher than silicon power devices. This allows for higher per-chip power density, leading to smaller devices and more compact packages. While research is continuing to reduce battery cost by increasing battery capacity—i.e., energy density—EV powertrains are also increasing power density (defined as the ratio of energy efficiency to overall size) by decreasing size, weight and cost. This is achieved by maximizing the use of SiC power switches, especially in on-board chargers (OBCs) and traction inverters in propulsion systems.

Additionally, SiC-based power devices are also capable of achieving switching frequencies 10× faster, up to at least 20 kHz in traction inverters and hundreds of kilohertz in OBCs. At these higher frequencies, the size of passive components like capacitors and inductors can be significantly reduced, allowing for smaller overall systems. SiC allows for higher withstand voltage, power and switching efficiency, simplifying the design of high-power traction inverters with significantly reduced losses.

EV system engineers are challenged to make the most of the potential of high-voltage technology through innovations involving power conversion and WBG semiconductors. The need for greater reliability and higher-power performance for EVs is continuously growing, as efficiency gains have a direct effect on increasing range per charge. However, it is still too difficult for EV designers to achieve a large increase in efficiency, given that most traction inverters are already operating at 90% or higher efficiency. The use of SiC for power switches enables higher power densities and switching efficiencies in EV powertrains.

Additionally, SiC-based power electronics enable EVs to achieve longer driving range, faster charging and lower total cost of ownership. The reduced power loss of SiC devices can also be exploited to reduce battery cost and size. Also, higher voltages reduce the need for large amounts of copper in the motor windings, resulting in smaller motor designs. These reductions in component size and weight help reduce the cost of EVs, significantly contributing to EVs’ cost parity, or even better, than traditional ICE vehicles. For a given power level and battery capacity, SiC power devices can be smaller in size, which results in clusters of EV subsystems with integrated propulsion systems. At the design level, the cost of the system can be minimized by eliminating or reducing the mechanical blocks for cooling and the amount of material for the passive elements and the case.

Overall, SiC power electronics are having a large global impact. The largest market segment for SiC in the coming years is definitely EVs, suggesting that the SiC technology market will grow faster than the EV market.

About US

Heisener Electronic is a famous international One Stop Purchasing Service Provider of Electronic Components. Based on the concept of Customer-orientation and Innovation, a good process control system, professional management team, advanced inventory management technology, we can provide one-stop electronic component supporting services that Heisener is the preferred partner for all the enterprises and research institutions.